- Your cart is empty

- Continue Shopping

Foundry Pro

Cast Iron Microstructure analysis Software – Foundry Plus

A software based on a touchscreen concept, Foundry Pro is the most comprehensive solution for cast iron industries. The software is used to estimate nodules, flake size and the class and number from 1 to 8 as per ASTM, JIS and ISO standards. Furthermore, the software includes various templates for reporting.

A software based on a touchscreen concept, Foundry Plus is the most comprehensive solution for cast iron industries. The software is used to estimate nodules, flake size and the class and number from 1 to 8 as per ASTM, JIS and ISO standards. Furthermore, the software includes various templates for reporting.

-

Option to get analysis report based on ASTM 247-67 or ISO 945_1 standards.

-

Nodules touching boundaries are excluded in analysis.

-

Artefacts less than 10 microns are excluded in analysis.

-

Nodules are separated from non-nodules on predefined spheroidicity.

-

The nodules/flakes form (designated by roman numbers I to VI) and size (designated by Arabic numbers 1 to 8) are reported.

-

The flake occurring in cast iron in the form I, are reported on the basis of type of distribution (designated by capital letters A to E) and on the basis of orientation.

-

The percentage of pearlite is calculated by excluding the graphite area.

-

The matrix of pearlite, ferrite, graphite and carbide are reported in etched sample.

-

Report is generated with specific international standards chosen by the user.

-

F% is reported in JIS method.

Image Editing

-

Cut, Copy, and Paste.

-

Selected copy by free hand AOL controlled by four arrow keys available on keyboard or mouse with zoom preview.

-

Crop, duplicate, restore

-

Resize

-

Compression

-

Conversion to another format such as BMP, JPG, TIF, PNG, GIF & PSD

-

Flood fill or spray with selected color at selected portion.

-

Grid creation; 5X5, 10X10 & 100X100 grids (or cells).

-

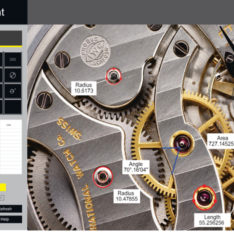

Drawing tool curve, line, square, and circle with node control and provision to change color & thickness of the line.

-

Write text in any color or font.

-

Pointer to place on an object in either of four directions with provision to change its color & thickness.

-

Eraser works only on line, arrow or on any drawing tool.(not on original image)

-

Camera Lucida

-

Montage feature to merge stored image together. Useful to Merge different focuses of same image.

-

Image stitching.

-

Highlighter.

-

Pixel by Pixel Correction by key board.

-

Multiple image folder with Search facility.

-

Filter application on selected area.

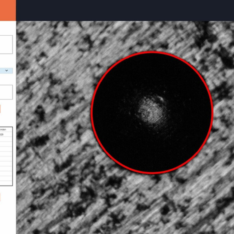

Edge Detection

-

Laplacing, Sobel, Krisch, Prewitt Gradient, Shift & Difference, Combine, Contrast Base, Quick, Range and Variance.

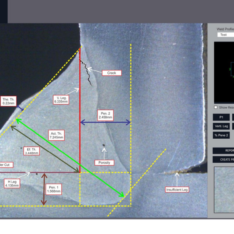

Morphometry

-

Skeletonizing, Pruning, SKIZ, Histogram Equalization, Histogram Smoothing, Histogram Peak, Histogram Valley, Segmentation by Over/Under and Quantized, Contoring, Dilation / Erosion on Binary, Gray & colored Images, Opening/ Closing on Gray & Binary Images, Special Opening/Closing, Split/Combine of RGB, YUV, YIQ, XYZ, & HSL, Changing any Image to 1, 4, 8 & 24 bits, Medial Axis.

-

Transformation, Halftone.

-

Image Addition, Image Average, Image Subtraction, Image Multiplication.

-

Roundness, Shape, Orientation, Elongation, Equal Circular Diameter, Equal Sphere Volume.

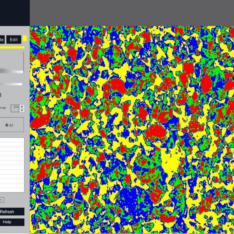

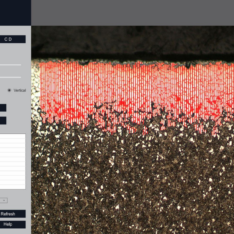

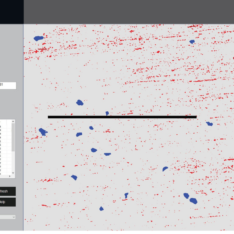

Cast Iron Analysis

-

The dedicated module determines flake size from 1 to 8 as per ASTM, JIS, and BIS & ISO standards. The type distribution percentage A, B, C, D, E is calculated interactive tools.

-

Flakes per square mm is also calculated simultaneously.

- Percentage of pearlite, ferrite, graphite and carbide is calculated from Etched sample automatically with predefined values.

View

-

Zoom in/out

-

Zoomed preview

-

Rotation at 90, 180,270 or custom

-

Image flipping; horizontal or vertical axis

-

Intensity histogram.

-

Image Information

-

Redo/Undo on all operations.

Image Processing

-

Background subtraction and contrast enhancement of color or grayscale images.

-

Arithmetic image functions (Boolean Math; Add, AND, OR, XOR, DIFF, MIN, MAX, +, -, /, *, And Simple).

Routine Filters

-

Invert, Brightness, Contrast, Hue, Saturation, Blur, Noise Remove, Emboss, Engrave, Gamma R, Gamma G, Gamma B, Yellow, Magenta, Cyan, Mosaic, Smooth, Desaturation, Pseudo Color, Colorize, Oilify, Despeckle, Posturize.

Special Filters & Karnels

-

High Boost, High Spatial, Low Pass Spatial, Ranking (Max, Med, Min), Point detection, Line detection, Homogeneity.

Locational

-

Centroid X, Centroid Y, Major X1, Major Y1, Minor X1, Minor Y1, Major X2, Major Y, Major X2, Minor Y2, Box X1, Box X2, Box Y, Box Y2 & Box Area.

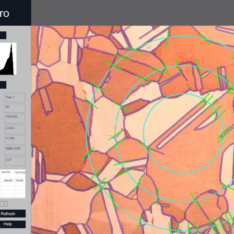

SG Iron Analysis

-

The module automatically analyzed & calculate Nodulins/Non Nodulins percentage. Determine its class and number from 1 to 8 as per ASTM, JIS, BIS & ISO standard s, Nodules per square mm is also on Etched sample it reported.

-

Determine percentage of pearlite, graphite, ferrite and carbide.

Report

-

Three options: Direct printout with original image processed Image & Tabular results.

-

Export to MS Office or Excel for further modification.